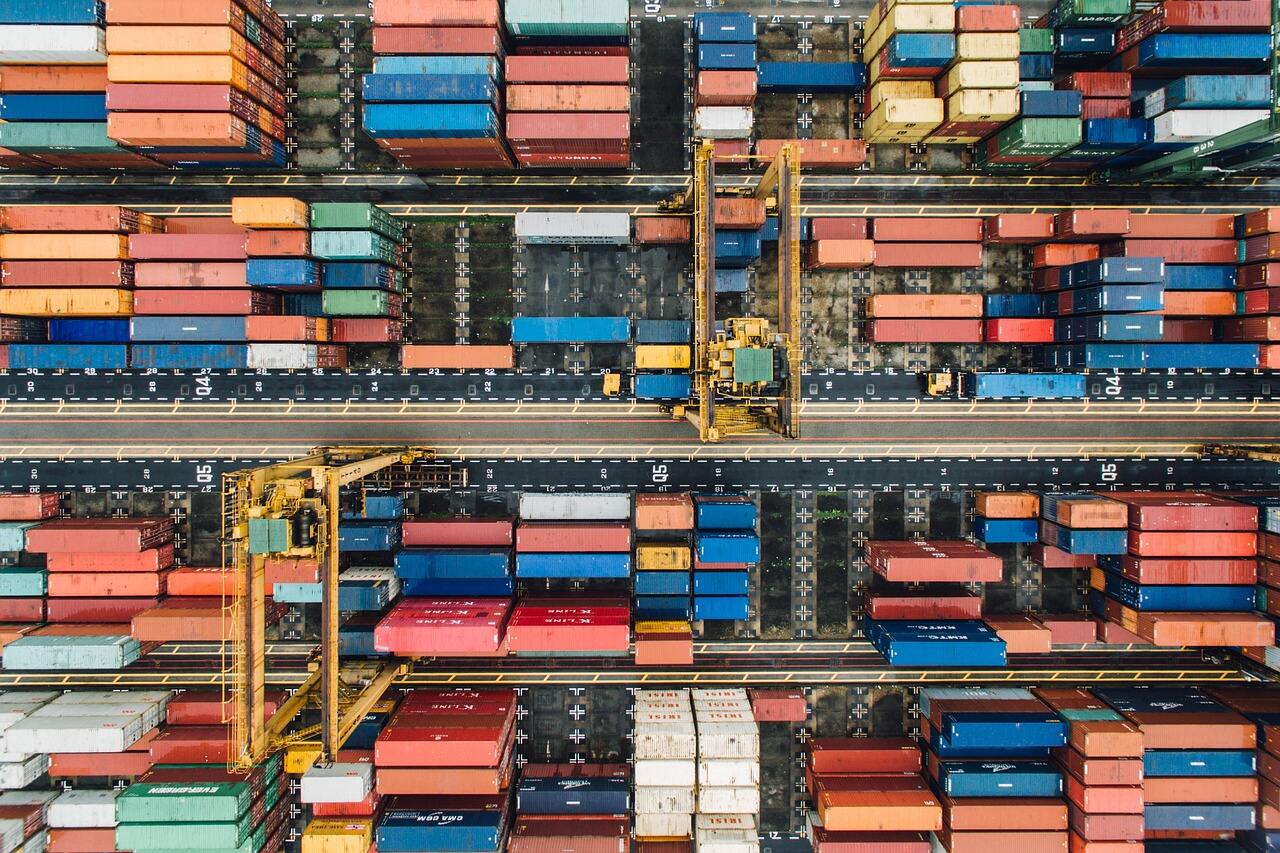

המרה של הלוגיסטיקה הבינלאומית באמצעות חדשנות דיגיטלית

הפארק הגלובלי של שירותי מובילות מטען עובר שינוי דרמטי, המניע על ידי התקדמות טכנולוגית ופתרונות חדשניים. ככל שהתחרות הבינלאומית ממשיכה לגדול, שיטות לוגיסטיות מסורתיות מתקדמות וברבות מקרים מומצאות מחדש לחלוטין באמצעות כלים דיגיטליים ותהליכי אוטומציה. המהפכה הזו לא רק משנה את הדרך בה מועברים מטענים מעבר לגבולות – היא משנה את מבנה שרשרת האספקה כולה.

שירותי מובילות מטען גלובליות מודרניות סומכות בהולכה רבה על טכנולוגיות מתקדמות כדי לאפשר זרימה חלקה של פעולות, להפחית עלויות ולספק שקיפות חסרת תקדים לבעלי העניין. מינהל בינה מלאכותית ועד טכנולוגיית בלוקצ'יין, חדשנות זו פותרת אתגרים עתיקים בתעשייה ויצירת הזדמנויות חדשות להגביר יעילות.

טכנולוגיות דיגיטליות המהפכניות את תפעול המטען

אינטליגנציה מלאכותית ויישומים של למידת מכונה

בינה מלאכותית הפכה להיות מנוע שינוי בשירותי משלוחים בינלאומיים, מציעה אנליטיקה חזוית שיכולה לחזות עיכובים במשלוחים, למקסם מסלולים ולאוטומט תהליכי מסמכים. אלגוריתמי למידת מכונה מנקשים כמויות עצומות של נתונים היסטוריים כדי לזהות דפוסים ולערוך תחזיות מדויקות בהולך על כל נושא, החל מבחירת המוביל האופטימלית וכלה בצוואר בקבוק פוטנציאליים.

מערכות חכמות אלו יכולות להתאים אוטומטית את החלטות הניהול בהתאם לגורמים בזמן אמת, כגון תנאי מזג האוויר, צפיפות בנמלים וזמינות קיבולת. גישה דינמית זו לניהול לוגיסטיקה הביאה לשיפורים משמעותיים בזמני משלוח וכושר ניצול המשאבים בכל הענף.

טכנולוגיית בלוקצ'יין וחוזים חכמים

יישום טכנולוגיית הבלוקצ'יין בשירותי משלוחים בינלאומיים הקדימה רמות של שקיפות וביטחון ללא תקדים במסמכי משלוחים. contrats חכמים מבוצעים אוטומטית כאשר מתקיימים תנאים מוגדרים מראש, מה שמפחית עיכובים בתשלום וסכסוכים, ומבטיח שכל הצדדים מקיימים את התנאים שנסכמו עליהם.

הטכנולוגיה של sổ המפצה המפוצל של הבלוקצ'יין יוצרת רישום בלתי ניתן לשינוי של כל פעולה וכל תנועה בשרשרת האספקלה, ובכך מונעת שגיאות במסמכי משלוחים ומצמצמת סיכונים של הונאה. השקיפות המוגדלת תרמה להאצת תהליך הפלת מכס ולחיזוק האמון מצד בעלי העניין.

שקיפות מוגדלת ופתרונות מעקב בזמן אמת

חיישנים של אינטרנט של הדברים (IoT) והתקנים מחוברים

אינטרנט הדברים (IoT) העניק מהפכה בדרכים שבהן שירותים בינלאומיים להובלת מטעים ועוקבים אחריהם. חיישנים חכמים המותקנים על מכולות ועל מטען מספקים נתונים בזמן אמת על מיקום, טמפרטורה, לחות, ותנאי טיפול. רמת המעקב הזו מובילה לשמירה על שלמות המטען ומאפשרת תגובה מיידית לכל בעיה העולה במהלך התחבורה.

התקנים מחוברים גם מאפשרים תחזוקה מונעת ותפעול מיטבי של הנכסים, מצמצמים את זמני הדינון של הציוד ומשפרים את היעילות הכללית של הפעולה. הנתונים שנצברים מהחיישנים תורמים להחלטות טובות יותר וstrateגיות ניהול סיכון.

פלטפורמות אנליטיקה ודוחות מתקדמות

פלטפורמות אנליטיקה מודרניות ממירות נתונים גולמיים לתובנות הניתנות למימוש עבור שירותים בינלאומיים להובלת מטענים. הכלים המורכבים הללו מספקים תובנה מקיפה בכל שרשרת האספקלה, ומאפשרים לבעלי עניין לזהות אי-יעילות ולשפר את הפעולה בזמן אמת.

באמצעות לוחות מחוונים המותאמים אישית ומערכות דוחות אוטומטיות, חברות יכולות לעקוב אחרי מדדי תפעול עיקריים, לעקוב אחרי צעדי מיקוד ולבצע ניתוח מגמות כדי לקבל החלטות המבוססות על נתונים. נראות מוגדלת זו הפכה להיות קריטית לשמירה על יתרון תחרותי בשוק הלוגיסטיקה הבינלאומי.

אוטומציה של תהליכים ואופטימיזציה של זרימות עבודה

אוטומציה של תהליכי רובוטיקה (RPA)

הטכנולוגיה של RPA מאיצה משימות חוזרות בשירותי מיקוד בינלאומי, מעיבוד מסמכים ועד הכנת הצהרות לאגף המכס. הרובוטים התוכנתיים פועלים 24/7, ומקצרים משמעותית את זמני העיבוד, וכן מונעים טעויות אנושיות בפעולות שגרתיות.

באמצעות אוטומציה של תהליכים ידניים, חברות יכולות להפנות מחדש משאבים אנושיים למשימות אסטרטגיות יותר, ולשפר את הפקטוריות והאיכות הכוללת של השירות. מערכות RPA גם מבטיחות עקביות בתפעול ואת עמידה בתקנות הבינלאומיות.

מסמכים דיגיטליים ופתרונות חסרי נייר

המעבר לתיעוד דיגיטלי הפחית באופן דרמטי את הנטל המנהלתי ש Beg associated with global freight forwarding services. מועדים אלקטרוניים, טופסי מכס דיגיטליים ובדיקות עמידה אוטומטיות הזרמו את זמני העיבוד ופחתו את העלויות הקשורות למערכות מבוססות נייר.

מערכות ניהול מסמכים מבוססות ענן מבטיחות שכל בעלי העניין יוכלו לגשת מיד למסמכים הדרושים, ותורמות לתהליך איטי וחלק של פיקוח מכסות ופחתה עיכובים בגבולות. המעבר הדיגיטלי הזה תרם גם ליציבות הסביבתית בכך שצמצם משמעותית את הצריכת הנייר.

מגמות עתידיות וטכנולוגיות בולטות

כלי רכב אוטונומיים ומסוקים

העתיד של שירותי משלוח מטען בינלאומי יושפע מהרחבת פתרונות תחבורה אוטונומית. משאיות נהיגה עצמאית וכלי רכב מונחים אוטומטיות כבר נמצאים בבדיקה בסביבות מבוקרות, עם הבטחה לפחית עלויות כוח אדם ולהגדיל שעות תפעול.

טכנולוגיית רחפנים (drones) צומחת גם כן כפתרון יעיל למסירת קילומטר הסיום ולתפעול מחסנים, במיוחד באזורים קשים להשגה או בתקופות שיא. חדשנות אלו צפויות לעצב מחדש את הנוף הלוגיסטי בשנים הקרובות.

אינטגרציה של רשת 5G וחישוב בקצה

הפצה של רשתות 5G בשילוב עם יכולות של חישוב בקצה תאפשר עיבוד מהיר של נתונים וקבלת החלטות בזמן אמת בשירותי משלוחים בינלאומיים. שילוב הטכנולוגיות הזה יאפשר יישומים מתקדמים יותר של אינטרנט הדברים (IoT) ויוביל לרמות חדשות של אוטומציה ובקרה.

חיבוריות מתקדמת תאפשר גם תקשורת טובה יותר בין אמצעי תחבורה שונים ומבין צדדים מעורבים, מה שיאפשר תפעול בין-תת-מגזרי יעיל יותר ויקצר את זמני המשלוח.

שאלות נפוצות

באילו אופנים הטכנולוגיה משפרת יעילות כלכלית בפיקוד על משלוחים?

הטכנולוגיה משפרת יעילות ביחסות תפעוליות בשירותי משלוחים בינלאומיים באמצעות ערוצים רבים, בהם אופטימיזציה של מסלולים, הפחתת עבודה 손ית, שיפור ניצול הנכסים והפחתת שגיאות בתיעוד. מערכות אוטומטיות וניתוחים חיזוייים עוזרים לזהות את אפשרויות המשלוח היעילות ביותר מבחינת עלויות, תוך מינימום של עיכובים ופחת הוצאות תפעוליות.

אילו תפקידים ממוקמים על ידי הבינה המלאכותית בתפעול משלוחים מודרני?

הבינה המלאכותית ממוקדת תפקיד מרכזי בתפעול משלוחים בינלאומי מודרני על ידי סיפוק ניתוחים חיזוייים, אוטומציה של תהליכי קבלת החלטות, אופטימיזציה של מסלולים ושיפור שירות הלקוחות באמצעות צ'אט-בוטים ומערכות תקשורת אוטומטיות. היא גם עוזרת בהערכת סיכונים ו lập תכנון ליכולת קיבולת.

עד כמה פלטפורמות המשלוח הדיגיטליות מאובטחות?

פלטפורמות ליווי מטענים דיגיטליות מטפלות במדדי אבטחה מרובים, בהם הצפנה, טכנולוגיית בלוקצ'יין ואימות פרוטוקולים מאובטחים. ביקורות אבטחה תקופתיות, עמידה בסטנדרטים בינלאומיים ומערכות זיהוי איום מתקדמות מבטיחות הגנה על נתונים ועסקאות רגישים.